Quay & Marine

In addition to standard quay and marine services you would expect from a modern well equipped container terminal, we also offer a number of additional services to meet both global and local requirements.

Out of Gauge (OOG) & Break Bulk

Our terminal have specialist teams and equipment for handling Out-of-Gauge or Break Bulk Cargo, designed to meet the needs of local markets and industries. To ensure your valuable cargo always remains safe, we only use highly trained and experienced operators, and suitable equipment. We also have specialized storage facilities for these types of cargo if required.

With Out-of-Gauge Cargo, the dimensions of the cargo exceed the flat rack or open top container by length, width or height, but a container can still be used. Out of Gauge cargo includes things like propellers, flanges or trucks.

Break Bulk significantly exceeds the size and/or weight of a standard container and is therefore handled as non-unitised cargo and normally placed on a bed of flat racks with a large number of lashing points. Beak Bulk cargo includes things like yachts, masts, industrial machines or train carriages.

At a glance

- We take care of special transit permits and customs clearance

- Specialised equipment and experienced stevedoring teams

- Book direct for better value

- We’ll help find the most cost-effective solution

- Strategic intermodal connections

- Warehousing and storage offered for OOG and Break Bulk

Roll-on/Roll-off (RoRo)

Roll-on/Roll-off (RoRo) terminals can handle everything from tractors, buses and trucks to oversized cargo loaded on special flatbed, mafi or lowboy trailers. We also specialise in new or used vehicle import and export and related services.

Our specialist RoRo terminals are strategically located next to intermodal transport networks for onward transportation via road, rail or inland water. Often the leading RoRo operator in the region, our high volumes mean that we offer high-frequency services.

Just-in-time delivery

We employ the latest computerised technologies to ensure that loading and unloading happens as quickly as possible, and enables you to meet just-in-time delivery schedules. For example, where applicable, we offer an efficient system for loading double-decker trains.

With many of our Terminals and Inland Service locations strategically located near to vehicle manufacturing plants, we can offer high-quality tailored services that ensure vehicles reach customers as quickly as possible and in perfect condition.

Efficient vehicle preparation services

Carrying out services such as vehicle pre-delivery inspections (PDIs), mechanical, painting and body repair services, PGF (protective guard film) removal and re-application, and de-waxing and waxing in large, continuous volumes, means that we’re extremely efficient. Many of our locations, for example, offer fully automated washing lines. On request we can add specific equipment, such as air conditioning, to make vehicles suitable for import and overhaul former rental and lease cars in our facilities.

Secure vehicle storage

Secure paved vehicle storage is never an issue, with more than enough space for the storage of cars, tractors, excavators and more. Security is enhanced through high-levels of illumination, fenced compounds and 24-hour CCTV coverage. Our facilities meet the highest local security standards including the International Ship and Port Facility Security (ISPS) and Construction Specifications Institute (CSI) classification.

For vehicles left in storage for a longer period, we offer long-term storage maintenance (LTSM) including the removal of foils, washing, battery check, battery charging and replacement, tyre pressure check, reporting and more.

Barge handling

Many of our larger terminals offer dedicated barge berthing. Discharging and loading of containers at the stack, and the majority of operations involving barge cranes are fully automated, offering speed, reliably and efficiency.

This also applies to most operations involving the barge cranes. Discharging and loading the containers onto and off the barge are the only processes that are carried out manually, as this benefits from eye-to-eye contact between the barge captain and the crane operator.

At a glance

- Sufficient depth for the largest barges

- Barge cranes capable of loading and unload the largest barges

- Dedicated barge container storage stacks

- Automatic handling of containers to barge cranes and stacks

- Fixed Windows for barges

- Real-time container status information

For a small fee, we are also able to offer a safe vehicle loading and discharge service for barges.

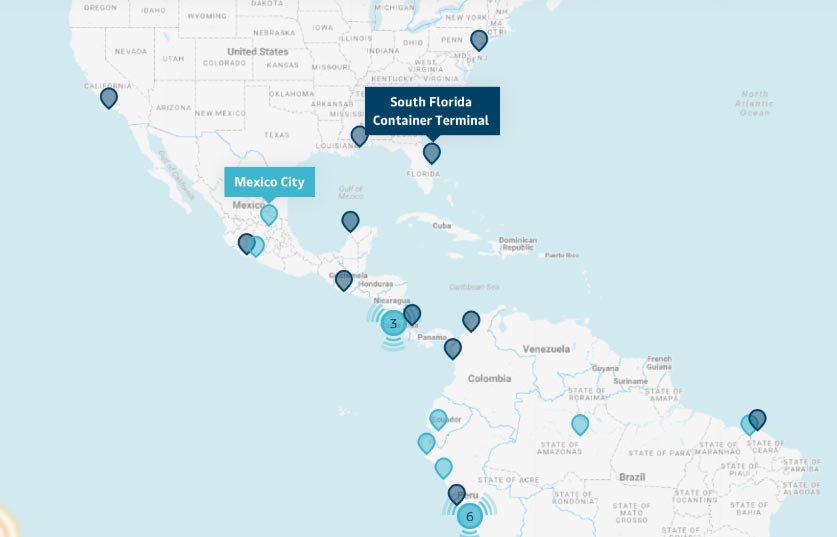

Service Locator

Use our interactive service locator to find out where we offer services around the world, or to discover what services are offered in a particular location.